Next Topic

Select SDGs to find out how we are taking action in support of the UN Substinable Development Goals

2022 ISRAEL CHEMICALS LTD. | ALL RIGHTS RESERVED

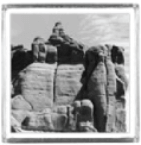

YPH JV, a joint venture with Yunnan Phosphate Chemicals Group Corporation Ltd. (“YTH”), operates an open-pit mining site named Haikou (the “Haikou mine”) that is located alongside the Haikou Town, in the Xishan district, near the city of Kunming. YPH JV holds two phosphate mining licenses that were issued in July 2015 by the Division of Land and Resources of the Yunnan district in China: (1) a mining license for the Haikou Mine in which the Company runs its operations and which is valid up to January 2043; and (2) a mining license for the Baitacun Mine, which expired in November 2018. The Baitacun Mine is located several kilometers from the Haikou mine, where mining activities have not yet commenced. In order to preserve the rights for the Baitacun mining license and facilitate its renewal in 2021, the Company paid an advance in an immaterial amount. The Company is examining the feasibility of renewing the Baitacun concession, and will base its decision, among other things, on the results of a phosphate reserves soil survey and on the understanding to be achieved with the authorities.

Access to Haikou mine is by means of a network of roads, as well as an accessible rail network that links to state rail lines. Considering the current operations at the Haikou mine, the average production capacity of YPH JV is approximately 2.2 million tonnes per year.

The Haikou mine has been in operation since 1966 and the concession area is spread over 9.6 square kilometers.

The Haikou mine is divided into four areas. The phosphate sources in areas 1 and 2 have been almost fully depleted. Mining in area 3 began in 2015, and mining activities in area 4 began at the end of 2017.

The phosphate is of a low organic type, and as such it is suitable for phosphoric acid production.

The mining in the Haikou Mine is via open mining using conventional methods by means of drilling and blasting, hydraulic excavators, mining trucks and tractors for mining phosphates.

In the first stage mining, the upper ground level is stripped and stored or spread out over mined areas for purposes of reclamation. In the second stage drilling, blasting and stripping of the upper overburden level is executed. The third stage mining of the phosphate is performed by drilling and blasting of every layer separately (between which an interborder layer exists having a thickness of 11 meters, which is also drilled, blasted and stripped) and the phosphate is then loaded onto trucks and transported to beneficiation plants.

Based on the patches’ appearance of the medium and high-grade phosphate, mining is performed through use of small mining tools, trucks with a capacity of 40 tonnes and excavators having a bucket capacity of 3 to 6 cubic meters.

Since 2009, YPH conducted a major project designed to eliminate all wastewater output. This “zero discharge” has been achieved via cascade and grade utilization, recycling collection, reuse systems and other actions. Despite the addition of ICL China YPH JV to our reporting scope in 2016, total ICL wastewater amounts remained almost the same in 2016-2017 compared with 2015. This has also enabled a significant decrease in wastewater intensity, resulting from phosphate production.

Close to the Haikou mine there are two beneficiation plants for flotation and scrubbing. These facilities are accessible by roads and the scrubbing plant is also accessible by train. Output from these facilities is sent to acids and fertilizers production plants, located several kilometres from the Haikou mine, which include four sulphuric acid factories, three green phosphoric acid factories, one factory for the manufacture of technical grade white phosphoric acid, one factory for the manufacture of food grade white phosphoric acid and an additional six fertilizer factories. These factories are powered by electricity generated from the sulphuric acid production process, as well as from the national power network. These facilities have been continuously developed and maintained for the last 40 years and are in good condition. Access to the production site is also by road and train.

ICL JV YPH strives to continuously improve the environmental protection of its operations and products. Adhering to the principle of "Protection with development, development with protection", YPH attaches great importance to mine reclamation, with a reclamation rate of more than 90%.

Close to the Haikou mine, there are two beneficiation plants, one for flotation and the other for scrubbing. The output of these facilities is designated for acids and fertilizers production plants, located several kilometres from the Haikou mine, which include four sulphuric acid factories, three green phosphoric acid factories, one factory for manufacturing technical grade white phosphoric acid and six fertilizer factories. These factories are powered by electricity generated from the sulphuric acid production process as well as from the national power network.

During 2020, the Company successfully completed its waste reduction plan as mandated by the law and regulations. Hazardous wastes produced by YPH JV are being strictly controlled, transferred and disposed through qualified enterprises. In addition, most of YPH JV's hazardous substances are utilized as raw materials and can also be found as finished products.

Where required, registrations for the storage, handling and transportation of these materials are acquired and maintained. Action plans and measurements are successfully performed to reduce the likelihood of releases of hazardous materials.

Annual land examinations are conducted in accordance with regulatory requirements.

In order to comply with local regulations, YPH has installed systems for removal of wastewater and its diversion from clean water sources, including transferring phosphogypsum water (which is created as a by-product of production processes) into designated ponds for further treatment.

In 2020, the Company initiated a project to expand its gypsum and floatation ponds, in full coordination with the local authorities, while obtaining all necessary permits required by national regulations. The project's completion is expected during 2021,and will enable YPH JV to use the expanded area of the ponds in the future.