Next Topic

Select SDGs to find out how we are taking action in support of the UN Substinable Development Goals

2022 ISRAEL CHEMICALS LTD. | ALL RIGHTS RESERVED

Bromine and its bromide derivatives represent an electrochemical couple around which various technologies have been developed for electrical energy storage applications. Realizing the opportunities that exist for innovative energy storage, ICL-IP has set up an electrochemical laboratory in support of developmental activities in bromine-based energy storage solutions. ICL’s expertise with bromine is already being used by developers of such systems.

ICL R&D developed technologies for extracting metal from ores and other sources. The technology uses bromine as an oxidizer that can leach metals effectively from refractory ores without pre-oxidation treatment. The process with bromine doesn’t involve cyanide at any stage, and therefore has the potential to be more environmentally friendly. The technology is also applicable to extract metals from e-waste and batteries. As the electric car market matures and batteries become even more prevalent, ICL expects this to be a new market in need for recycling of metals.

ICL Industrial Products is making significant breakthroughs in the marketplace by expanding its sustainable and efficient flame retardants portfolio. New products are in line with an ICL-IP resolution to provide sustainable flame retardants to the marketplace.

Microbial contamination in water systems is a well-known phenomenon leading to biofilm, bio-corrosion, infectious diseases, poisonous metabolites & disruption of production processes.

ICL-IP’s Microbial Solutions have been leading the development of Bromine based solutions for controlling microbial growth, disinfection and biofilm treatment and prevention. These solutions improve the energetic efficiency and heat transfer in industrial water systems, prevent corrosion and extend equipment operation life.

ICL-IP has also developed (in collaboration with ICL’s open Innovation unit) a product that reduces the need for biocides with the help of signaling molecules.

ICL has developed an innovative product for handling Bromine spill incidents. BromoQuel™ offers a safe response and an immediate suppression of bromine vapor and liquid spills.

Read MoreThe UNEP Global Mercury Partnership is an entity dedicated to protecting human health and the environment from the impacts of mercury and reducing its release on a global basis. It is carrying on the international negotiations for establishing a legally-binding agreement regarding mercury emissions.

Coal burning power plants are today’s largest source of mercury pollution in the environment. The Merquel® product line, launched by ICL Industrial Products at the end of 2008, is based on inorganic bromides, which enable efficient neutralization of mercury – a 90% reduction in mercury emissions.

The use of agricultural films is an established part of agriculture. The polymer films provide protection against weed growth, prevent the soil from cooling down and reduce the drying out of the substrate. This results in faster and better crop growth.

A disadvantage of these films is that they have to be collected after harvesting or, in the case of biodegradable material, rot over a long period of time.

By adding fine powdered calcium or magnesium phosphate as a filler, it has been possible to create a decomposition process much faster, so that the polymer material is decomposed in a shorter time.

The filler is added during the production of the film and is integrated into the thin polymer matrix. The decomposition process occurs much faster and the assimilation and mineralization process is completed earlier.

The use of agricultural films is an established part of agriculture. The polymer films provide protection against weed growth, prevent the soil from cooling down and reduce the drying out of the substrate. This results in faster and better crop growth.

A disadvantage of these films is that they have to be collected after harvesting or, in the case of biodegradable material, rot over a long period of time.

By adding fine powdered calcium or magnesium phosphate as a filler, it has been possible to create a decomposition process much faster, so that the polymer material is decomposed in a shorter time.

The filler is added during the production of the film and is integrated into the thin polymer matrix. The decomposition process occurs much faster and the assimilation and mineralization process is completed earlier.

ICL is providing a whole range of phosphate-based solutions for the dairy industry. One of the products is JOHA KM2, a complexing Calcium-Ions material that prevents insoluble Calcium salt formation. It increases the run time of dairy processing equipment. This results in less frequent cleaning steps, and improvement in the efficiency of cleaning. JOHA KM2 also allows for efficient heat transfer during the heating process, which reduces energy consumption.

On top of that, savings are achieved by reducing the number of cleaning cycles in a milk evaporator. That results in:

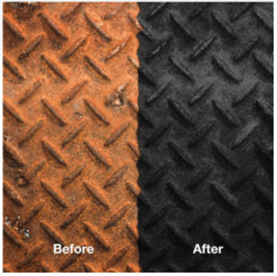

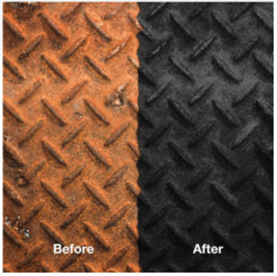

ICL’s rust converters help to preserve steel and allow the re-use and restoration of rusted metal to a finished look vs. disposing of the rusted steel parts.

By complexation with iron oxide, our products create an impermeable black iron oxide layer which slows down any further asset corrosion.

Rust converters chemically bond to the rust and seal it. This is a low-cost solution to an expensive problem.

By 2030, increase substantially the share of renewable energy in the global energy mix

By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities.

By 2030, achieve the sustainable management and efficient use of natural resources

By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse